Time:2 pm, September 28, 2018 (first lecture)

(This lecture will be held every Monday from October 8th until the end of October)

Place: Conference Room 104, Building 1, State Key Laboratory of Silicon Materials, Yuquan Campus

Title:New silicon single crystal casting method

Speaker:Kazuo Nakajima

Inviter:Academician Deren Yang

Bio:

Professor Kazuo Nakajima is an internationally renowned scholar with internationally recognized achievements in semiconductor materials and applications. Professor Kazuo Nakajima's research includes semiconductor crystal materials, solar cells, semiconductor phase diagrams, plastic deformation of VI (Si and Ge) crystals, and crystal lenses. These studies have had a profound impact on the growth and application of semiconductor crystals. It mainly includes the following aspects: (1) Professor Kazuo Nakajima developed the dendritic casting method, obtained high-quality polysilicon and high-efficiency solar cells (created the world's highest record of large-scale solar cells at that time); (2) developed Non-contact niobium (NOC) method to prepare high-quality silicon large single crystal ingots, and for the first time obtained solar cells with the same conversion efficiency as monocrystalline silicon solar cells grown by Czochralski method; (3) prepared with microscopic composition distribution SiGe polycrystal, the crystal solar cell has higher conversion efficiency than Si polycrystalline solar cell; (4) experimentally and theoretically determined multi-component semiconductor phase diagram, and finally grown by liquid phase epitaxy (LPE) method InGaAsP and InGaAs epilayers on InP, InGaAsP semiconductor lasers and InGaAs avalanche optoelectronics The development of diodes has made a great contribution; (5) It has been found that plastic deformation at the melting point makes it easy to obtain crystal lenses of Si and Ge, which can make X-ray equipment compact and can be used on satellites.

Professor Kazuo Nakajima has published more than 350 papers in more than 30 years of research, citing more than 5,000 papers; completed nearly 20 books; and has nearly 35 authorized patents. Professor Kazuo Nakajima's development and contribution to semiconductor materials technology won the Outstanding Engineer Award at the 5th Asian Crystal Growth and Crystal Technology Conference in 2011 and the Japan Crystal Growth Society Award in 2014.

Abstract:

During Zhejiang University, I will carry out work on “Research and development of new Si single crystal casting growth methods for solar cells, especially non-contact niobium (NOC) method”, as well as related postgraduate courses and exchange of experience.

The dendritic casting method obtains high quality cast polycrystalline silicon by a method of controlling the crystal structure, which strongly affects the existing casting method. The dendritic casting method proves that the quality of the cast crystal can be greatly improved by controlling the nucleation at the bottom of the crucible and the crystal structure at the initial stage. Inspired by the dendritic casting method, several important techniques for growing Si ingots by controlling the crystal structure have been developed, including quasi-single crystal casting, high efficiency (HP) casting, and NOC. We have accumulated a wealth of experience in this area.

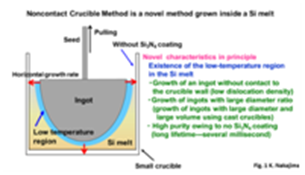

This problem also exists with ingots grown by casting methods, and the crystal quality limit depends on the residual stress of the crucible wall. To solve this problem, we have developed the NOC method of using a casting furnace to produce high quality large Si single ingots. Since the NOC method uses a casting furnace, productivity can be greatly improved while reducing the cost of Si single ingot growth. In the NOC method, the Si melt has a large low temperature region at the center of its upper portion to allow natural crystal growth inside thereof without coming into contact with the crucible wall. The low temperature region means a region where the melting temperature is kept lower than the surrounding Si melt. Using this method, a maximum monolith having a diameter of 45.0 cm and a diameter ratio of 0.90 was obtained using a crucible having a diameter of 50 cm. Using the same solar cell structure and process, the conversion efficiency of the p-type Czochralski (CZ) single crystal was 19.1%, and the highest conversion efficiency of the p-type single crystal of the NOC method was 19.14% (average conversion efficiency of 19.0%). A solar cell having a conversion efficiency of a CZ solar cell was obtained for the first time by a NOC method using a casting furnace.

Zhejiang University has a good research foundation for the growth of high-quality uniform large Si single ingots based on casting methods, and has a common goal with the NOC method, namely, increasing production and reducing costs. Our research experience and foundation will help to continue the work of silicon single crystal growth in Zhejiang University, and promote the further improvement of HP method, quasi-single crystal casting method and NOC method.